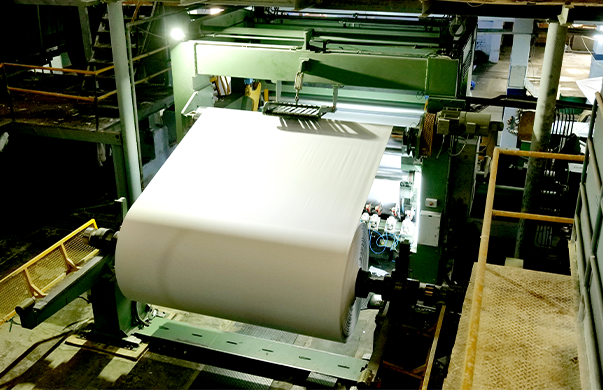

Since 1995, Naini has gone a long way. Starting with a single paper machine with a capacity of 30 TPD and progressing, we collaborated with technology to become more environmentally friendly and cost-effective over time. Let’s take a look at our history to discover how we evolved as an ethical and ecologically conscious firm.

Start with One paper machine with production capacity 30 TPD kraft paper

- One more paper machine and pulp mill added with a production capacity "100 TPD" writing & printing paper

- FBR installation to recover caustic from waste black liquor

Major modification in paper machine-1 to increase production capacity and shift “Kraft & Absorbent” to “Writing & Printing”

Installed continuous digester & ODL for bagasse pulping

Installed Bi nip press on pm-2

Film press, post dryer, NOSS centricleaners and pressure screen, Metso scanners, Globe high speed rewinder installed on pm-2

ODL installed on pm-2 pulp mill

- Installed head box (Module Jet), BVG Size Kitchen on pm-2

- Major Modification of film press, shoe press, DCS & IMCC, Complete automation of pm-2.

- Voith hard nip calendar, Duo former, syncro cutter installed onpm-1

- Installed ESP for boiler No – 3,4,5,6

- Hood System (FOMAT) , Stock Refiners (ANDRITZ)

- Close hood, kadant condensate recovery system

Gapcon transfer roll, air shooters for tail threading, ceramic center roll

IBS-ultra high pressure clothing cleaning system system, Andritz soft wood refiners on pm-2

Commissioned 12 MW Captive Power Plant with 60TPH, 88Ata FBC boiler

- Installed Hard-nip Turbo Calendar, Dandy Rolls, I-table, Pasaban Cutter, Folio Ream Wrapper

- New globe Rewinder , Ream Packing Machine

- ICONE couch roll, ream packing machine

- High efficiency energy recovery boiler

- Lime Kiln and two stage causti sizing

- 350 TPD Hard Wood fibre line with ECF bleaching

- 10.2 MW turbine

- 9 TPD integrated clo2 plant based on R-6 process

- Enhanced Production capacity 9200 TPM to 10500 TPM